preface

In recent years, China's sulfur dioxide pollution is quite serious, and has become one of the most serious countries in the world. Due to economic and technological reasons, the emission of sulfur dioxide in China has been out of control, with the emission increasing year by year. The area of acid rain is expanding year by year, posing a serious threat to the ecosystem, building materials, agriculture and human health. On August 3, 2006, the State Environmental Protection Administration disclosed at a news conference that the total emission of sulfur dioxide in 2005 reached 25.49 million tons, ranking first in the world. Among them, the sulfur dioxide emissions of thermal power plants account for more than half of the total emissions of the country. China's energy composition is dominated by coal, and its consumption accounts for about 70% of the total primary energy consumption. This situation will not change for a long time in the future. Therefore, grasping the main problem of sulfur dioxide emission in the power industry and strengthening the governance can, to a great extent, alleviate the uncontrolled state of sulfur dioxide emission in China.

At present, there are many technologies for flue gas desulfurization at home and abroad, such as wet, dry and semi dry methods. Among them, the desulfurization medium (limestone) used in limestone gypsum wet desulfurization technology is low in cost, the desulfurization technology is mature, the desulfurization efficiency is high, and the desulfurization by-products are harmless to the environment and convenient for comprehensive utilization, so they are widely used. In China, limestone gypsum wet process has been used to desulfurize flue gas in many thermal power plants since 1990s. After years of operation, not only the environment has been greatly improved, but also successful experience has been accumulated in the research, development and utilization of its by-product flue gas desulfurization gypsum. Therefore, in the future, large and medium-sized thermal power plants of 200 MW and above in China will mainly adopt this desulfurization technology, and the output of flue gas desulfurization gypsum is expected to reach more than 8.5 million tons by 2010. Strengthening the research on the resource utilization of desulfurized gypsum, broadening its application fields and improving its utilization rate is not only a powerful promotion to the realization of the goal of flue gas desulfurization in thermal power plants, but also meets the requirements of accelerating the development of circular economy and building a conservation oriented society in China. The basic properties of 15 FGD gypsum samples from different regions were studied in this paper.

(1) collection of desulfurized gypsum samples

The desulfurized gypsum samples collected are all in wet powder form and come from Inner Mongolia, Shanxi, Jiangsu, Zhejiang, Guangdong and other places. The color of the samples is different, most of them are yellow, and there are also a few white and gray samples. According to the production process of desulfurized gypsum, the main components of desulfurized gypsum and natural gypsum are calcium sulfate dihydrate. Under the normal operation of the desulfurizing unit, the gypsum color should be close to white; However, as desulfurized gypsum is a chemical gypsum produced by flue gas desulfurization, its impurities will affect the color of gypsum, such as light yellow and grayish brown due to containing impurities such as calcium carbonate and magnesium carbonate; When the dust collector is unstable and the flue gas containing more fine-grained fly ash enters the absorption tower, the color is gray.

(2) particle gradation analysis

The particle size of 15 samples collected was determined by laser particle size analyzer according to the method specified in the quality standard and analysis method of flue gas desulfurization gypsum formulated by the German Industrial Association (vgb).

As there are high requirements on the fineness of limestone powder or lime powder as the flue gas desulfurization absorbent, as shown in Table 1, the particle size of more than 90% of limestone needs to be less than 40 μ m. In this way, it is not easy to cause machine wear to the flue gas desulfurization system, so the desulfurized gypsum formed by flue gas desulfurization is finer than the natural gypsum, and its average particle diameter D50 is generally not more than 90 μ m. And the particle size distribution range is narrow.

It can be seen from table 2 that the samples with D50 average particle size of 60-80um account for 53% of the total samples, the proportion of samples with average particle size of 80-95um is 27%, and the proportion of samples with average particle size of 37-50um is 20%. This measurement result is different from the average particle concentration of desulfurized gypsum in some data that is 30-60 um. It can be seen from the particle size distribution diagram of the samples that the content of particles with particle size less than 20um is small in most samples, and the content of particles with particle size greater than 140um is also small. The particle distribution peak shape of the samples is narrow, and the particle size of most samples is mainly distributed in the range of 40-110um (as shown in Fig. 1 and Fig. 2).

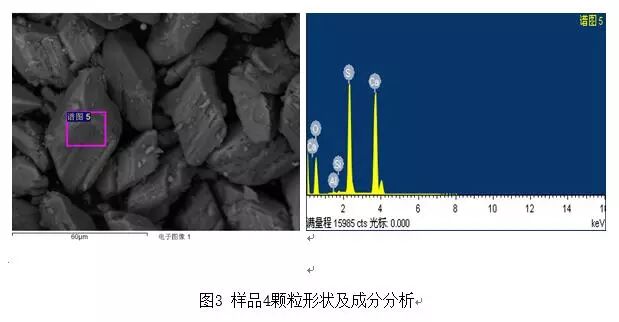

(3) microscopic observation of desulfurized gypsum particles

The particle size and chemical composition of desulfurized gypsum were analyzed by SEM.

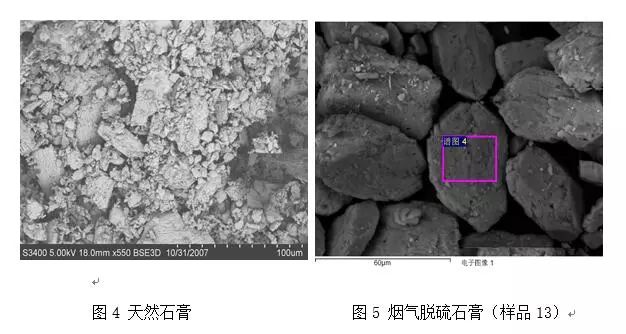

It can be seen from Fig. 4 that the natural gypsum particles are bonded together, while the desulfurized gypsum (Fig. 5) exists as separate crystalline particles. There is pressure in some crystals of desulfurized gypsum, while natural gypsum mainly exists in rhyme state. The coarse particles of natural gypsum after grinding are mostly impurities; The coarse particles of desulfurized gypsum are mostly gypsum and the fine particles are impurities.

According to the above SEM analysis atlas, most of the desulfurized gypsum particles are hexagonal inclined columns, but the particle size of most of the samples is not uniform, for example, there are more large particles in samples 7, 8 and 9, while the particle size of samples 1 and 13 is relatively uniform, which is consistent with the previous test results of desulfurized gypsum particle size distribution. According to the elemental analysis of desulfurized gypsum samples by energy spectrum, the main components are calcium sulfate, and the impurities mainly contain mg, Al, Na, K, Fe, Si and a small amount of chlorine. However, the content and type of impurity elements attached to the particles of the same sample may not be the same.

Therefore, the crystal form of desulfurized gypsum is obviously different from that of natural gypsum according to the scanning pictures of electron microscope. There are many fine particles of natural gypsum, and the difference between coarse and fine particles is obvious. The crystal form is plate-shaped, and the crystal is coarse and irregular; The desulfurized gypsum particles are relatively uniform, the crystals are in short column shape, the length and diameter are small, and the appearance is regular.

(4) determination of attached water content and crystal water content of desulfurized gypsum

From the above purity of desulfurized gypsum, the purity of the collected desulfurized gypsum samples is more than 90%, and because flue gas desulfurization requires strict CaO content in limestone or lime powder, the chemical composition of desulfurized gypsum is relatively stable, and its quality is better than that of ordinary natural gypsum, which provides the possibility for desulfurized building gypsum to replace natural building gypsum in gypsum products.

It can be seen from the above table that the collected samples with moisture content of desulfurized gypsum within 10% (including 10%) account for 53% of the collected samples; The samples with water content of 10% - 15% (including 15%) account for 40% of the total sample volume; However, the water content of sample 15 is too high, as high as 21%, which may have a great relationship with the desulfurization process of the power plant. If the moisture content of gypsum is too high, it will not only affect the normal operation of desulfurization system and equipment, but also cause certain difficulties in gypsum storage, transportation and post-processing. Therefore, it should be controlled.

(5) chemical composition analysis

The analysis room of China University of Geosciences and the national building materials certification center respectively provide test data for the analysis of desulfurized gypsum samples. At present, China University of Geosciences has provided test results (due to the large number of samples and projects tested, they are listed in two tables).

5.1 soluble impurities and their hazards

Mg2 +, Cl -, Na +, K + etc. affect the adhesion with paper; Part of the magnesium salt is soluble, which is different from natural gypsum. The crystallization of Na +, K +, and Mg2 + causes the products to return to frost and affects the setting performance of gypsum. As unprotected gypsum products are sensitive to weathering, the content of water-soluble magnesium salt [MgO], sodium salt [Na2O] and potassium salt [K2O] should be reduced. Chloride has a significant effect on the bonding performance of desulfurized gypsum. Gypsum products such as gypsum board have requirements on the chloride content in gypsum. Too much calcium sulfite in hemihydrate will lead to high water content of desulfurized gypsum and high water absorption of hemihydrate gypsum. Sometimes the setting time and strength of cement will be affected by using cement retarder.

Therefore, in case of excess, water washing, classification, neutralization and other purification and dehydration facilities shall be added to purify the desulfurized gypsum.

5.2 insoluble impurities and their hazards:

The particles of alumina and silica in desulfurized gypsum are relatively coarse, which has great influence on the grindability of desulfurized gypsum. Its high content will reduce the grinding efficiency and increase the powder cost. These large particles that are not suitable for grinding will also affect the application range of gypsum. Iron oxide will affect the grindability and whiteness of desulfurized gypsum. High iron oxide content, poor grindability and low whiteness of desulfurized gypsum. Incomplete combustion of pulverized coal particles affects the whiteness and adhesion of products.

(6) determination of heavy metal content and radioactivity of desulfurized gypsum

6.1 heavy metal content of desulfurized gypsum

It shall be determined according to the method specified in gb18582-2001 limits of harmful substances of interior decoration materials.

It can be seen from the table that the heavy metal content of desulfurized gypsum meets the requirements of the limit value of heavy metal content in gb18582-2001 limits of harmful substances in indoor decoration materials.

6.2 desulfurization gypsum radioactivity

The radioactivity of desulfurized gypsum shall be determined according to the method specified in GB 6566-2001 limits of radionuclides in building materials.

It can be seen from the above table that the radioactivity index of desulfurized gypsum shall meet the requirements of the national standard GB6566-2001 radionuclide limits for building materials.

7 conclusion

In this paper, the physical and chemical properties of FGD gypsum samples collected from different regions in China were studied. The research shows that although desulfurized gypsum is the same as natural gypsum in main components, its particle shape, particle size distribution and chemical composition are obviously different from natural gypsum, mainly as follows:

(1) From the perspective of gypsum crystal, there are many fine particles of natural gypsum, and the difference between coarse and fine particles is obvious. The crystal form is plate-shaped, and the crystal is large and irregular; The desulfurized gypsum particles are relatively uniform, the crystals are in the shape of hexagonal short columns, the length and diameter are relatively small, and the appearance is relatively regular.

(2) From the perspective of particle size distribution, the size of natural gypsum particles varies greatly, and the particles with different particle sizes account for a certain proportion in gypsum particles; The particle size of desulfurized gypsum is uniform, and the large particles (more than 140 μ m) And small particles (less than 10 μ m) And 80% of the particles were concentrated in 40-80 μ m。

(3) From the perspective of chemical composition, the purity of desulfurized gypsum is higher than that of natural gypsum, and the content of calcium sulfate dihydrate is more than 90%. However, its impurity composition is relatively complex, which has a great relationship with the process conditions. For example, the content of soluble salt and chloride ion is higher than that of natural gypsum, which is one of the main reasons for the performance problems of desulfurized building gypsum products, such as frosting and reduced adhesion.

(4) The content of heavy metals and radioactive indexes in desulfurized gypsum are obviously lower than the requirements of relevant national standards, and the environmental protection performance of desulfurized gypsum is safe.

Contact: Mr Zhou

Phone: 86-13833456715

Tel: 0311-84311301

Email: jingjinjixie@sina.com

Add: East Fan Zhuang Village Jinzhou Town jinzhou City,Shijiazhuang,Hebei, China