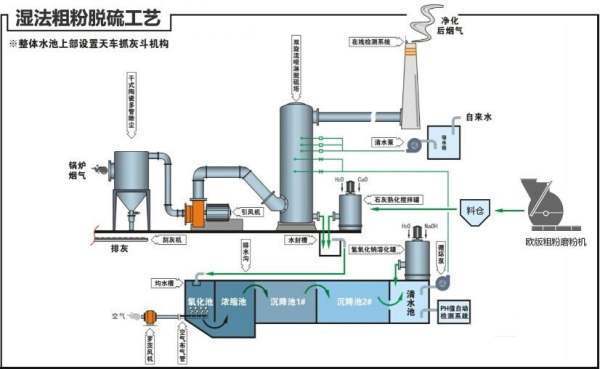

Power plant desulfurization process flow diagram and principle

The desulfurization technology principle:

Flue gas entering into the wet desulfurization absorption tower, and from top to bottom spray alkaline limestone slurry droplets countercurrent contact, HCL acid oxide of SO2 and other pollutants, HF is absorbed, such as flue gas can be fully purification; After absorbing SO2 reaction to generate CaSO3 slurry by in situ forced oxidation and CaSO4 crystallization generated • 2 h2o, get the goods after dehydration desulphurization by-product gypsum, finally realizes the sulfur-containing flue gas comprehensive management.

Power plant desulfurization process flow diagram:

Extended information:

Desulfurization, referring to remove sulfur content in fuel before combustion and flue gas emissions before desulfurize process. Is one of the important technical measures of prevention and control of atmospheric pollution.

Now generally have combustion desulfurization method before and after combustion and combustion desulfurization 3 kinds. With the development of industry and people living standard rise, the thirst for energy is also increasing, SO2 of coal-fired flue gas has become the main cause of air pollution. Reducing SO2 pollution has become a priority in today's atmosphere environment governance. A lot of flue gas desulfurization technology has been widely used in industry, its governance of all kinds of boiler and incinerator exhaust also has important practical significance.

Contact: Mr Zhou

Phone: 86-13833456715

Tel: 0311-84311301

Email: jingjinjixie@sina.com

Add: East Fan Zhuang Village Jinzhou Town jinzhou City,Shijiazhuang,Hebei, China